| CW series eddy current brake | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hits:29899 AddTime:2023/10/3 10:49:34 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

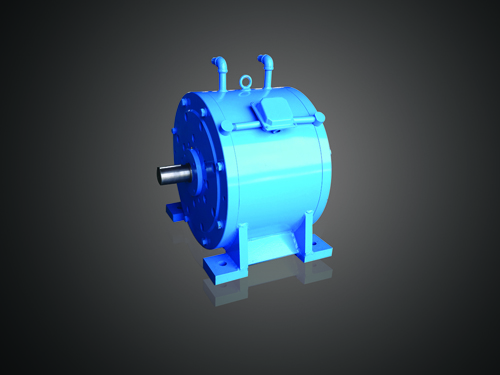

Eddy current brake, as a kind of load, mainly used to measure the dynamic mechanical properties of test equipment, it and other control measuring instrument can be eddy current dynamometer.Can be used for internal combustion engine, motor, gas turbine, automobile and machinery components performance test, compared with other dynamometer device, the CW series dynamometer device has higher reliability, stability, and practical.

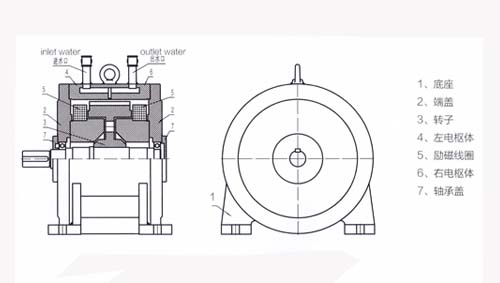

The CW type eddy current brake (with groove wheel), by the rotor stator (including around the armature, excitation coil, end cover, bearing cover), frame composition.

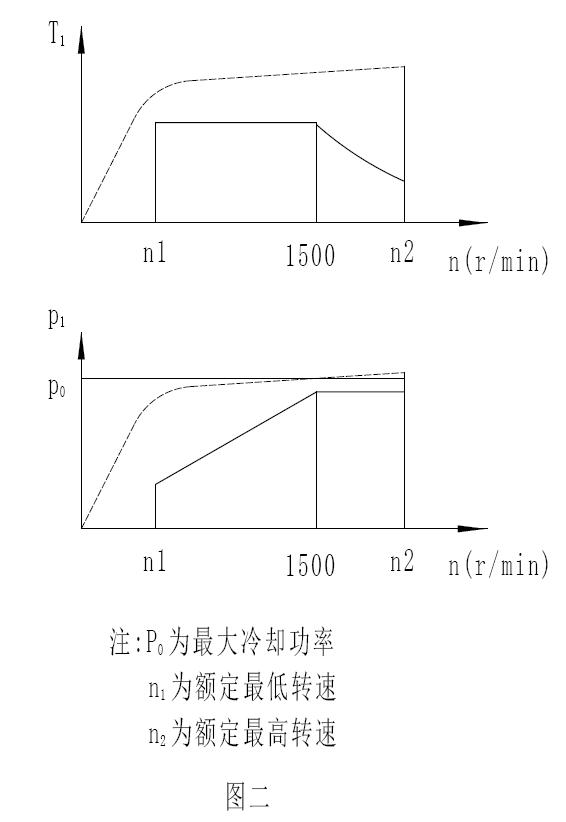

4.3 Characteristic curve

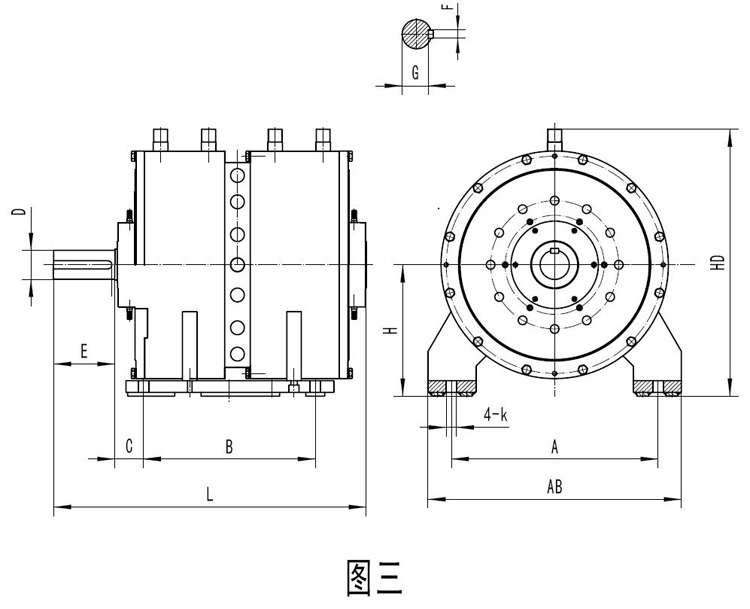

Note: P0: Maximum cooling power n1: Rated minimum speed n2: Rated maximum speed Figure 2 5. Outlinge and installing dimension (As following table)

Figure 3

Note: The outlinge and installing dimension of standard product are shown as above table. Please in kind prevail. 6. Usage, transportation and storage of electric eddy current brake 6.1 The environment temperature of electric eddy current brake is 0℃ — +40℃, the relative humidity is not more than 85%. Install the device below 1000 meters above sea level. 6.2 Electric eddy current brake should be installed on a solid foundation without any shock vibration and the surroundings shall be free of acid, alkali, salt and other harmful substances. 6.3 Transportation and storage temperature: - 30 ℃ ~ + 50 ℃ (hydrops in the cooling system shall be emptied); Transportation can be carried out in the case of packing. The speed shall keep less than 30+5 km/h on tertiary highway. Both railway and waterway are permitted. 6.4 Because the power generated by the tested machine is absorbed by electric eddy current brake, CW series electric eddy current brake shall be equipped with water in case of operation. Or the electric eddy current brake would be burnt out. With the exception of a few heat dispersed through the shell, most heat generated by the power absorption is concentrated on the eddy current component. Therefore, as shown in Figure 1, there are several cooling water flow channels on the back of vortex ring. The external cooling water passes the flow channel and makes heat exchange with magnetic ring. The heated water runs away through pipes. Cooling water is an important guarantee to ensure the normal operation of electric eddy current brake. The pipe with special dimension shall be installed at the inlet and outlet of eddy current brake. To inspect the leakage of water supply system and the prescribed value of water flow by means of water testing. The cooling tap water and water in circulating pool can be used as the cooling water. When using circulating pool, the heat dissipation of cooling water shall be taken into consideration with the inlet temperature of≤25℃. The cooling water shall be clean tap water without salt, alkali and other corrosive substances, which can prevent the rapid formation of incrustation. Users can identify and judge the local water quality and take measures to prevent incrustation formation, especially in hard water areas. Or the channel of eddy current brake would be blocked quickly. And also, users can add anti-rust agent and anti-fouling additives to prolong the service life of eddy current brake. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 【Refresh】【Favorites】【Print】 【Close】 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Previous:DWZ eddy current brake Next:Expansion drum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Robot Joint Module Test Stand

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Electric dynamometer

- Magnetic powder dynamometer

- Hydraulic dynamometer

- Chassis dynamometer

- Drill pipe test bench

- Actuator, worm gear box, test bench

- Engine, axle, gearbox, PTO test bench

- Reducer test bench

- Traction machine test bench

- Motor test bench

- Planetary reducer test bench

- RV, Harmonic Test Bench

- Hydraulic pneumatic motor test bench

- Hydraulic wrench test bench

- Testing software

- Slewing bearing test bench

- Acquisition instrument

- New energy vehicle transmission test bench

- Non-standard custom test bench

- High and low temperature test chamber

- coupling

- Industrial chiller

- Torque calibration